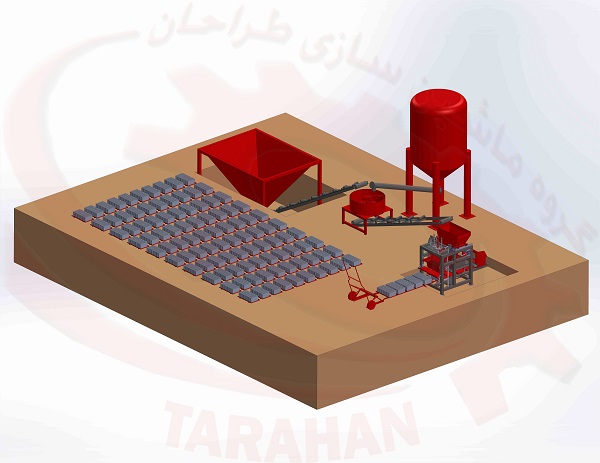

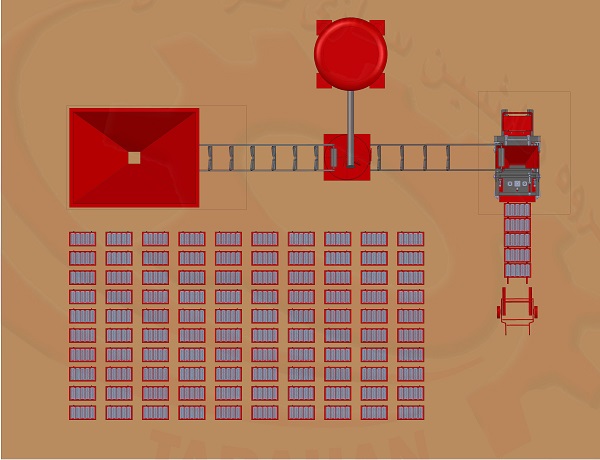

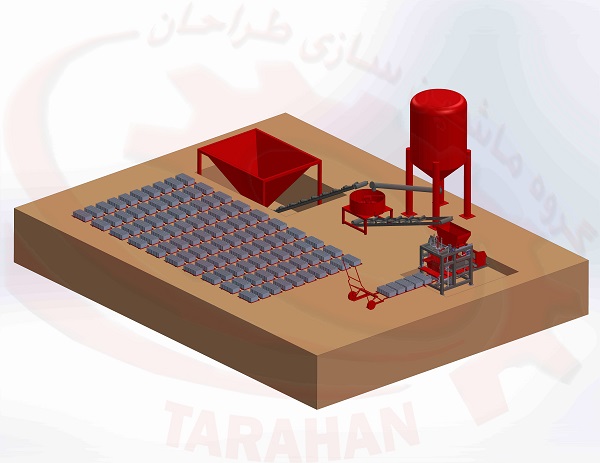

Simple or Manual Concrete Production Line

A manual production line is a system where the output products are manually transported. This can be done using two different methods:

- Special wheelbarrow system – Products are placed on pallets directly on the ground.

- Elevator/rack system – Pallets are stacked on wheeled racks using an elevator system, and a single operator manually transfers them to the designated area.

Machines in the Production Line:

- Hopper or Feeder

A single-bin or dual-bin feeder is used to weigh raw materials (sand, gravel, pumice). It is recommended to use a 30-meter dual-bin feeder equipped with a digital weighing system for this production line. - Conveyor Belt

Two conveyor belts are used:- One transports raw materials from the feeder to the mixer.

- The other moves mixed materials from the mixer to the press machine.

- Cement Silo

The cement silo is used for storing cement. - Cement Screw Conveyor

The cement screw conveyor transfers cement from the silo to the mixer. - Concrete Mixer

It is recommended to use dry mortar mixers, specifically the horizontal DM.H model. - Concrete Product Manufacturing Machine

The recommended models for this production line are TM 502 and TM 400. - Special Product Transport Wheelbarrow

This special wheelbarrow is used to transport products on pallets from the machine output to the curing section. - Metal Pallet

Pallets are essential components of the production line, as they hold the concrete products from the production stage until they are fully dried.