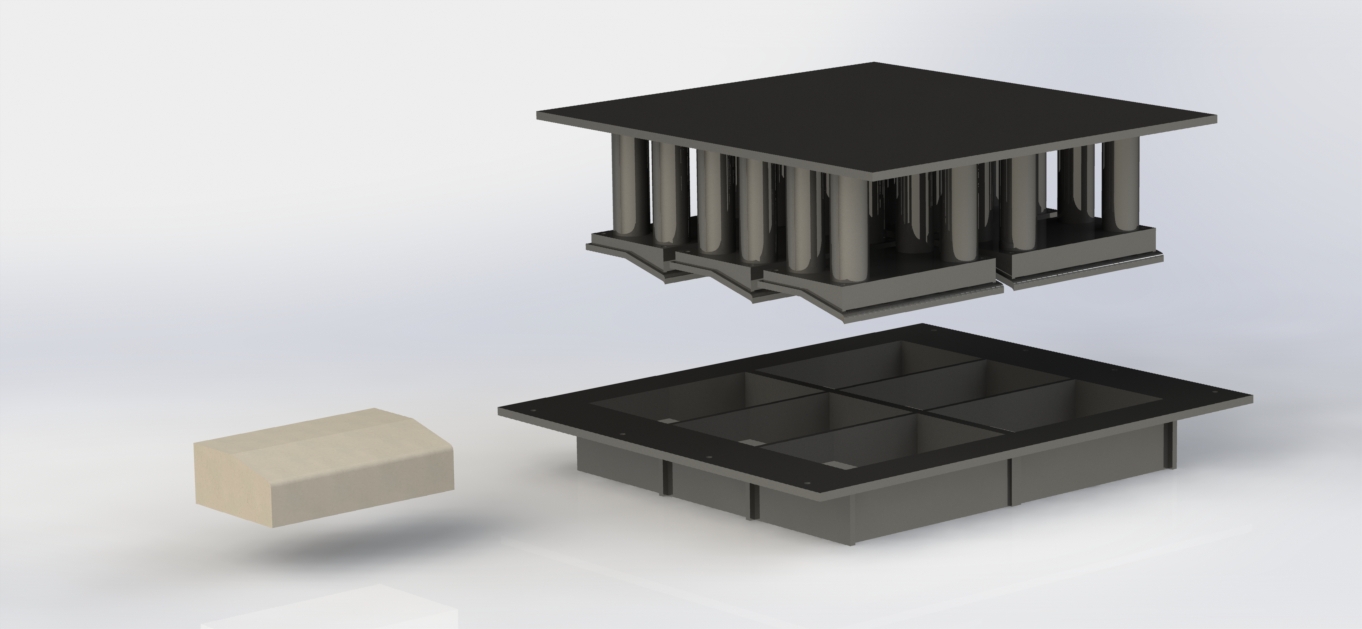

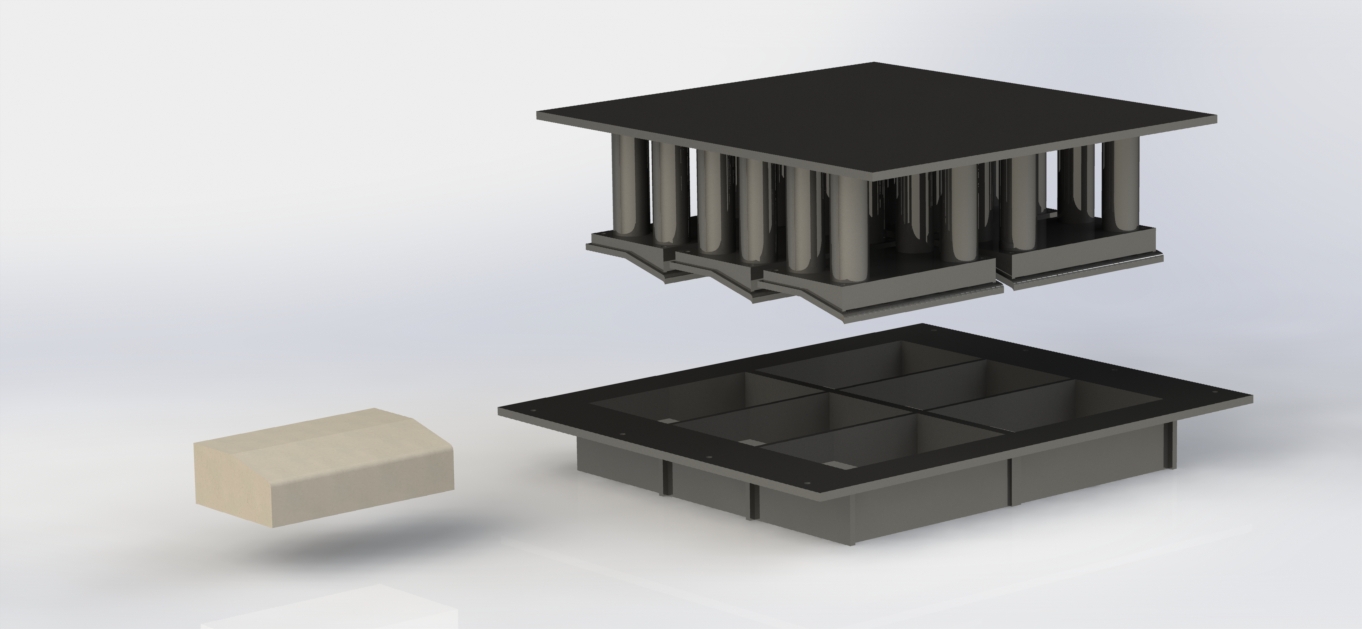

Concrete Curb Molds

We specialize in designing and manufacturing various concrete curb molds based on customer specifications for all types of mobile and stationary curb-making machines (Paving, Piusing).

Material and Manufacturing Process

- Concrete curb molds are typically made from ST-37 steel plates.

- For increased durability, customers can request wear-resistant steel plates.

- High-precision laser cutting ensures accuracy in mold production.

- Standard 50 cm curb molds for stationary machines are designed horizontally, while those for mobile machines are designed vertically.

Manufacturing Steps:

- Customer Confirmation:

- The curb size and type are finalized based on customer requirements.

- Laser Cutting:

- Steel plates are cut with high-precision laser machines for smooth and accurate edges.

- Assembly & Welding:

- Skilled mold-makers assemble and weld the parts, ensuring a robust final product.

Pricing of Concrete Curb Molds

The price of a concrete curb mold depends on:

- Curb size

- Number of curbs per mold

- Material type

- Curb-making machine model

For a custom price quote, please contact our company and consult with our specialists.

Frequently Asked Questions (FAQs)

Do you sell second-hand curb molds?

No. We do not recommend purchasing second-hand molds due to two reasons:

- Used molds are rarely in good condition unless lightly used or never utilized.

- Each mold is designed specifically for different curb-making machines, and modifying a used mold for a new machine can be costly and problematic. A new mold is always the best option.

What is a concrete curb?

Concrete curbs are precast concrete elements used as side barriers in road construction, including:

- Asphalt, concrete, and gravel roads

- Grass or mosaic pavements

- Boundaries between sidewalks and streets