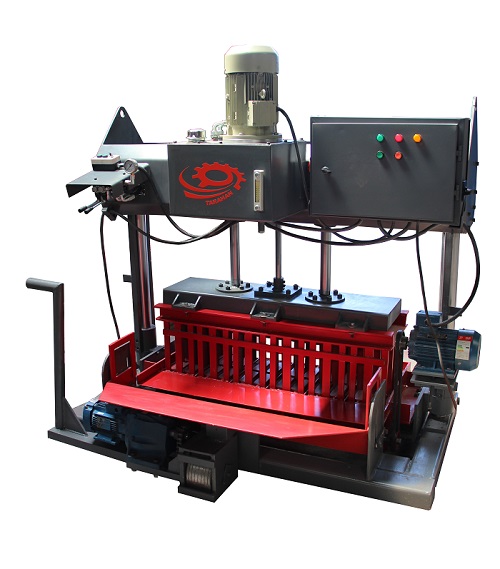

M.KB Semi-Hydraulic Block-Making Machine

Tarahan M.KB Semi-Hydraulic Block-Making Machine

The M.KB semi-hydraulic block-making machine is a mobile (egg-laying) machine designed for producing various types of concrete blocks, including:

- Wall blocks

- Ceiling blocks

- Partition blocks

- Interlocking puzzle blocks

- Concrete curbs up to 30 cm width

The pressing and molding system of this machine operates hydraulically, while the mold is manually fed using a hand-operated trowel.

Requirements for Operating the Semi-Hydraulic Block-Making Machine:

To operate the M.KB semi-hydraulic block machine, the following are required:

✔ A block mixer for mortar preparation

✔ A level concrete surface for smooth operation

✔ Two wheelbarrows

✔ At least three workers

Specifications of the Tarahan Block-Making Machine:

✔ 3 kW electric motor for the hydraulic system

✔ 1.5 kW electric motor for machine movement

✔ All wear-exposed parts are coated for durability

✔ Can be designed to operate on single-phase electricity

✔ Daily production capacity: 1,500 – 2,000 concrete blocks

✔ Ability to produce curbs up to 30 cm width

✔ Manual feeding using a wheelbarrow

✔ Adjustable vibration power

✔ Equipped with an electrical panel

Required Additional Equipment:

✔ 25A power supply

✔ Standard wheelbarrow

✔ 500-liter mixer (DM.V model)

✔ A 500-square-meter level concrete surface

Brands Used in Tarahan Block Machines:

✔ Motogen Tabriz electric motors

✔ Turkish hydraulic control levers

✔ Italian hydraulic hoses

✔ LS or Hyundai (Korea) electrical panel components

🎥 M.KB Block-Making Machine Video

⚠ Due to price fluctuations, installment sales for block-making machines are currently unavailable.

Frequently Asked Questions (FAQ)

Can a mobile block-making machine produce curbs?

Yes, but only concrete curbs with a maximum width of 30 cm.

Can a hydraulic block-making machine run on single-phase electricity?

Yes, but the machine’s power will be reduced, and its price will increase. Therefore, it is recommended to use three-phase electricity.

What is the difference between the M.KB mobile block-making machine and the M.KH model?

In the M.KB model, mold filling is done manually using a trowel, whereas in the M.KH model, a hydraulic mortar feeder is used.

Can the semi-hydraulic mobile block-making machine operate on an uneven (non-concrete) surface?

No. Due to the uneven surface, the machine will have difficulty moving, and the quality of production will be affected.

Can the M.KB block-making machine produce concrete pavers?

Yes, but no mobile block-making machine can produce pavers to standard quality. For high-quality paving stone production, a stationary machine is required.

Price of Block-Making Machines on Divar (Online Marketplace)

One of the ways to check block-making machine prices is to browse listings on Divar, where you can compare different used machines in various cities.

Prices of used block-making machines on Divar depend on:

- The model of the machine

- Its condition (new or used)

- Additional components (e.g., block molds, concrete mixer, etc.)

Before purchasing, it is always recommended to check the official price from the manufacturer and compare it before purchasing a second-hand machine.

Buying a Used Block-Making Machine on Divar

❌ If you are not familiar with block-making machines, it is not recommended to buy a used machine from Divar.

Used machines:

- Do not come with a manufacturer warranty

- Do not include technical support

- May have defects or require costly repairs

👉 It is recommended to purchase machines that have a manufacturer’s label or plate indicating the year of production and technical specifications. Avoid buying machines with unknown origins.

Price of a 12-Mold Automatic Block-Making Machine

A 12-mold automatic block-making machine refers to a fully hydraulic mobile block machine that can produce 12 concrete blocks (20 cm) per cycle.

This machine features a material storage hopper, making it commonly referred to as a “hopper block-making machine”.

Technical Specifications of the Kadona Block-Making Machine

The semi-hydraulic block-making machine is equipped with single-action jacks, meaning that the jacks lower using gravity (free-fall or hammering motion), applying impact instead of pressurized force.

At Tarahan, this design weakness has been improved by using double-action jacks, converting the system to a press mechanism to:

✅ Increase the lifespan of machine components

✅ Improve production speed

Operating System:

- The movement of the machine is controlled by an electric motor and manual steering.

- The vibration system in some models uses two oil-based or electric side vibrators, while others feature a full-surface vibration system directly on the mold.

- The Tarahan semi-hydraulic block-making machine uses a full-surface vibration system, which offers better performance compared to oil-based vibrators.

How to Operate a Block-Making Machine

The semi-hydraulic block-making machine requires one operator to control its movement, pressing, and vibration systems.

Operating Steps:

- Using a wheelbarrow, the raw materials (mortar) are poured onto the machine’s tray.

- With a trowel, the operator manually moves the material into the concrete block mold.

- Vibration is activated to compact the material inside the mold.

- Once the mold is completely filled, the pressing system is engaged.

- The pressing process is repeated 4 to 5 times (hammer press system).

- The upper punch (press head) remains on the mold, while the lower matrix (bottom mold) is lifted using the hydraulic lever.

- The finished concrete blocks are released onto the ground and left to cure and dry.

Important Tips for Using a Block-Making Machine:

Avoid using the vibration function when the mold is empty, as this can loosen screws and damage the machine.

At the end of each workday, the mold must be cleaned to prevent hardened residue from damaging the mold.

Always use the machine on a level concrete surface, ensuring smooth operation and higher-quality blocks.

Before moving the machine, make sure the mold is not in contact with the ground.

Materials Used in Concrete Block Production

To manufacture concrete blocks, various materials can be used. However, cement is always a primary ingredient. Other materials may include:

- Sand

- Pumice

- Perlite

- Leca (lightweight aggregate)

In recent years, pumice-based blocks have become more popular, particularly in Western Iran, due to high-quality pumice mines in Tabriz. Using pumice results in lighter blocks, commonly known in the market as lightweight blocks.

Buying a Second-Hand Block-Making Machine

This section provides information on used block-making machines and other related equipment.

Guide to Buying a Block-Making Machine, Curbs, and Paving Stones

This article is designed to give a complete understanding of block-making machines, including:

- Technical terms

- Types of machines

- Production specifications

Our goal is to help customers and buyers make informed decisions when purchasing block-making machines directly from the manufacturer.

Additionally, this guide will assist in choosing the right machine based on production volume, type of blocks, and investment budget.