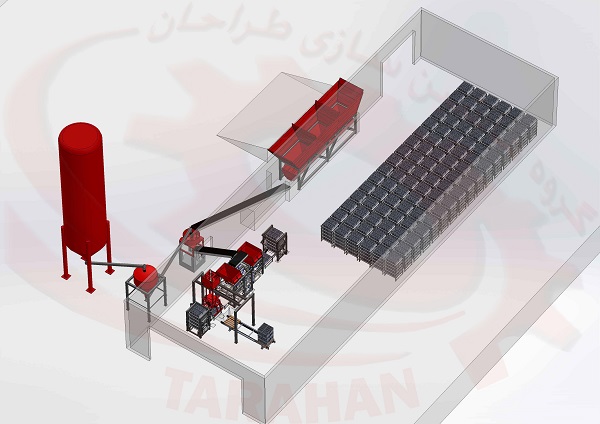

Automatic Concrete Production Line

The automatic production line is designed with a product collection system from pallets (robotic stacker / paddle robot). The machinery in this line is equipped with a PLC system, allowing for fully automated operation to reduce labor requirements compared to a semi-automatic production line.

Machines Used in the Production Line

- Hopper (Feeder)

- Used for precise and digital weighing of raw materials (sand, gravel, pumice, etc.).

- Conveyor Belts

- Two conveyor belts:

- One transports raw materials from the feeder to the mixer

- The other moves the mixture from the mixer to the press machine

- Two conveyor belts:

- Cement Silo

- Used for storing cement.

- Cement Screw Conveyor

- Transfers cement from the silo to the mixer. The number of screw conveyors depends on the number of cement silos.

- Concrete Mixer

- For this line, it is recommended to use a dry mortar mixer, specifically the DM.H horizontal model.

- Lowering Robot

- Located behind the press machine, this robot collects empty pallets and feeds them into the press.

- Stacking Robot (Cuber)

- This robot collects and arranges dried products from production pallets onto sale pallets.

- Paddle Robot

- Performs the same function as the stacking robot, and either can be chosen based on investment level or other factors.

- Concrete Block & Paver Machine

- Machines from the TM series are used in this production line.

- Lifting Robot

- Placed in front of the press machine, this robot stacks pallets with products in layers.

- Metal Pallets

- Pallets are an essential part of production, as the products remain on them from production until drying.