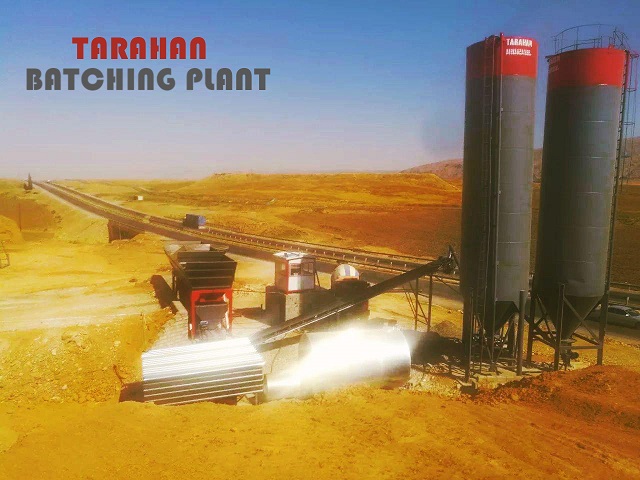

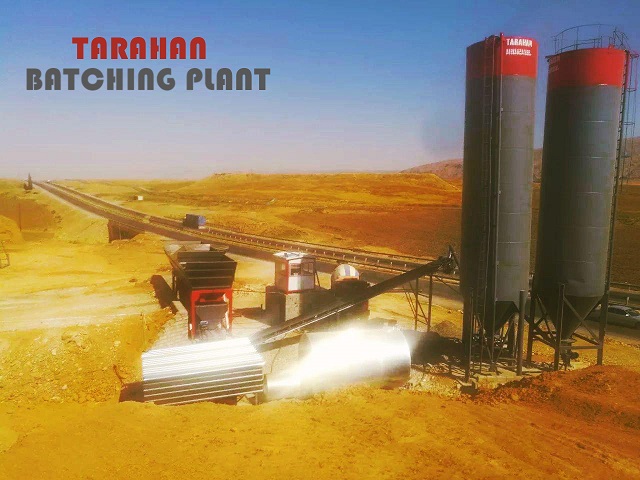

Batching Plant 80 S.BP – Tarahan

All Tarahan batching plants are designed to meet customer requirements. From the initial design phase to final construction, all necessary site data is collected before the batching plant is custom-designed and built.

Features of Tarahan Batching Plants:

- High-quality and precise concrete production with a fully automated computer system

- Custom plant designs based on customer needs

- Use of high-quality electrical components from reputable brands

- Compatibility with different mixer types

- High-capacity production capability

- Easy maintenance and repairs

Specifications:

- Capacity: 80 cubic meters per hour

- Mixer Specifications: 2 cubic meters

- Cement Weighing Scale Capacity: 1000 kg

- Cement Weighing Scale (additional): 1500 kg

- Water Meter: 2 inches

- Cement Screw Conveyor: 8 inches

- Power Requirement (Dry System): 30 kW

- Power Requirement (Wet System): 104 kW

- Required Land Area: 800 square meters

Batching Plant Video:

Related Information:

Safety in Installation and Use of Batching Plants

Before purchasing and installing a batching plant, it is essential to review the safety guidelines and correct installation procedures.

Second-Hand Batching Plants

A used or second-hand batching plant must be fully tested before purchase to ensure its proper functioning.

Batching Plant Pricing

The price of a batching plant depends on its production capacity and whether it operates as a wet or dry batching system.

What is a Batching Plant?

A batching plant accurately weighs the required materials to produce concrete.

Types of Batching Plants

- Feeder Batching Plant (Fixed, Portable, or Mobile Batching Plant)

- Dragline Batching Plant

How a Batching Plant Works

The batching feeder, controlled by load cells, weighs the aggregate materials and transfers them via a conveyor belt according to the preset ratios.