Concrete Wall Blocks

Concrete wall blocks are used today in various designs, including plain, interlocking (tongue and groove), and decorative types.

Structurally, these blocks are typically single-layer with two or three hollow cores.

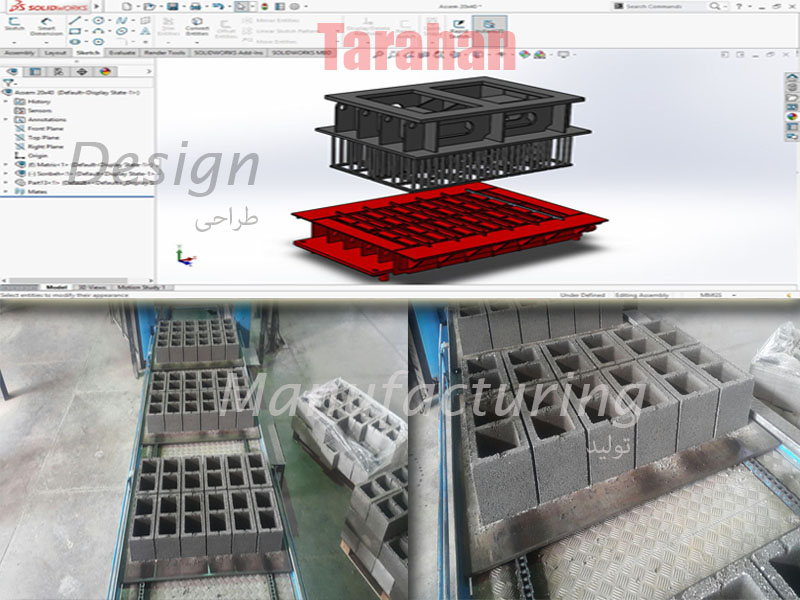

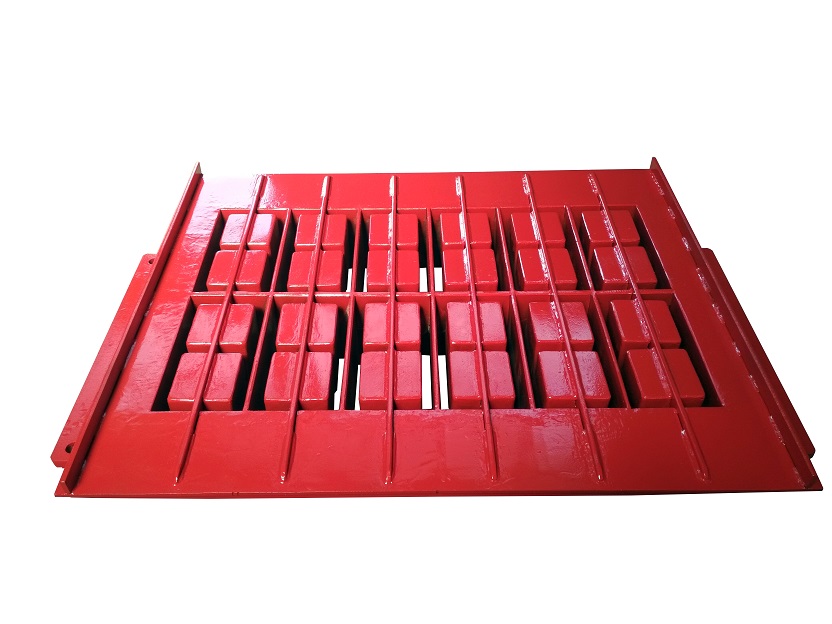

Manufacturing Concrete Wall Block Molds

The manufacturing process for concrete wall block molds, which are a type of cement block molds, follows these steps:

First, after determining the block specifications, including size, number of hollow cores, wall structure (single or interlocking), and design (plain or decorative), the technical unit at Tarahan Machinery designs the mold based on the model of the machine on which the mold will be installed.

Once the mold design is completed, the blueprint is sent to the cutting unit, where high-quality steel sheets are selected and cut using laser machines according to the specified dimensions.

Frequently Asked Questions

Do you design and manufacture single block molds?

No, single block molds are not cost-effective for either the mold manufacturer or the block producer, so they are not manufactured.

Do you sell manual block molds for hand-operated machines?

Yes, Tarahan designs and manufactures block molds for all types of block-making machines, including fixed, mobile, hydraulic, and manual machines.

What is the price of a concrete block mold?

The price varies based on block specifications, such as dimensions, number of holes, interlocking features, and the machine model used.

The production capacity of each mold also affects the price.

Once the technical details are finalized, the cost is calculated based on:

- Material type (steel grade).

- Cutting method (laser cutting, oxy-fuel cutting, or manual cutting).

- Additional treatments (e.g., heat treatment for enhanced durability).

How can I purchase a concrete block mold?

To order a block mold, you can contact the provided phone numbers or send a message with a picture of your machine and the required block to +98 914 584 1914 to receive a price quote.