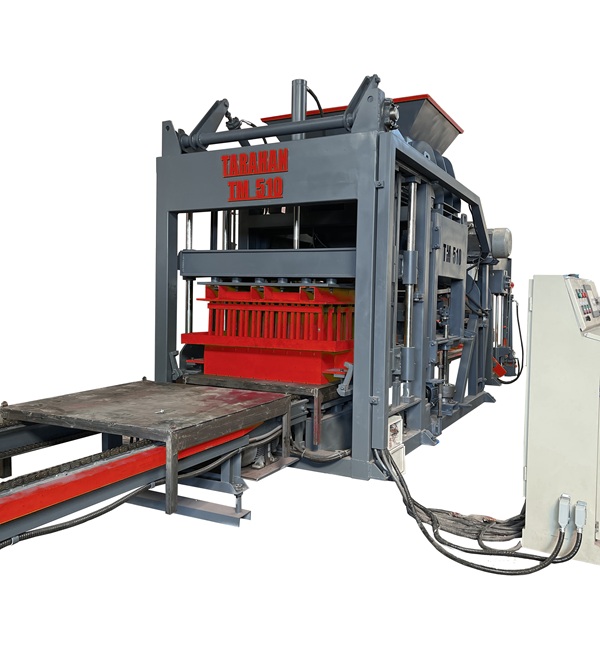

Tarahan Semi-Hydraulic Curb Stone Machine – M.KC Model

The Tarahan mobile curb stone machine (Kadona model) is capable of producing various types of concrete curbs up to 50 cm in height.

This semi-hydraulic curb stone machine has a production capacity of 500 to 1000 concrete curbs per shift, using a simultaneous press and vibration system.

The Tarahan curb stone machine, with its pressing system (not hammer-based) and adjustable vibration, ensures the production of high-quality concrete curbs.

Technical Specifications of Tarahan Curb Stone Machine:

- One 2 HP electric motor for moving the curb stone machine.

- Two high-power vibrators, located at the front and rear of the mold, with adjustable power settings.

- One 5 HP electric motor for the hydraulic system.

- Machine weight: 1500 kg.

Required Equipment and Conditions:

- 800-liter mixer.

- Three-phase 32A electrical power supply.

- At least two high-base wheelbarrows.

- A flat, leveled concrete floor (minimum 500 square meters).

Video of the Kadona Curb Stone Machine

Frequently Asked Questions

Can a mobile curb stone machine also produce concrete blocks?

Yes, it can, but it will cause high mold and machine wear. Also, changing the mold requires skill and takes time, so it is better to use a separate machine for block production.

Can a hydraulic curb stone machine run on single-phase electricity?

Yes, but it will reduce machine power and increase costs. Therefore, using three-phase electricity is recommended.

What is the difference between a semi-hydraulic and a fully hydraulic mobile curb stone machine?

A semi-hydraulic curb stone machine requires manual feeding with a wheelbarrow for each production cycle, while a fully hydraulic curb stone machine has a built-in mortar storage silo, eliminating the need for manual feeding.

Can a semi-hydraulic mobile curb stone machine be used on an uneven surface (non-concrete ground)?

No, uneven ground will cause movement issues, and the produced curbs will not meet quality standards.

What types of curbs can be produced with a mobile curb stone machine?

All standard market curbs can be produced using this machine.

Second-Hand Curb Stone Machine Prices

Like any other used machine, second-hand curb stone machines are cheaper than new ones.

The price of used curb stone machines varies depending on the model, usage, and accessories such as molds and concrete mixers.

Before purchasing, it is recommended to get a price estimate from the manufacturer to assess the real market value of the machine.

It is not advisable to buy a second-hand curb stone machine from online marketplaces like Divar unless you are familiar with how these machines operate.

Used machines do not come with a manufacturer’s warranty or support, and any defects or malfunctions will be the buyer’s responsibility.

When buying a used machine, it is best to choose one with an original manufacturer’s label or serial plate indicating the production year and technical specifications.

Curb Stone Machine Price List

Mobile curb stone machines are available in semi-hydraulic and fully hydraulic models.

However, they are often incorrectly referred to as semi-automatic and automatic curb stone machines.

Due to fluctuations in currency exchange rates and steel prices, curb stone machine prices may vary.

For the latest price list of curb stone machines, please contact us.

Fully Automatic Curb Stone Machine

A fully automatic curb stone machine is the same as a fully hydraulic mobile curb stone machine.

These machines feature a built-in material storage silo, making them also known as hopper curb stone machines.

A fully hydraulic curb stone machine can produce 1500 to 2000 curbs in 8 hours, depending on the technical specifications and operating speed.

At Tarahan, this machine is available as the M.CS Fully Hydraulic Curb Stone Machine.

Manual Curb Stone Machine Price

Manual curb stone machines are traditional and outdated.

Due to higher quality standards set by regulatory organizations, curbs produced by manual machines do not meet industry standards and are no longer in demand.

Moreover, manual curb stone machines have very low production capacity, making them uneconomical, as their production costs are high.

Therefore, it is recommended to use hydraulic curb stone machines for concrete curb production.