Machine Concrete Paver

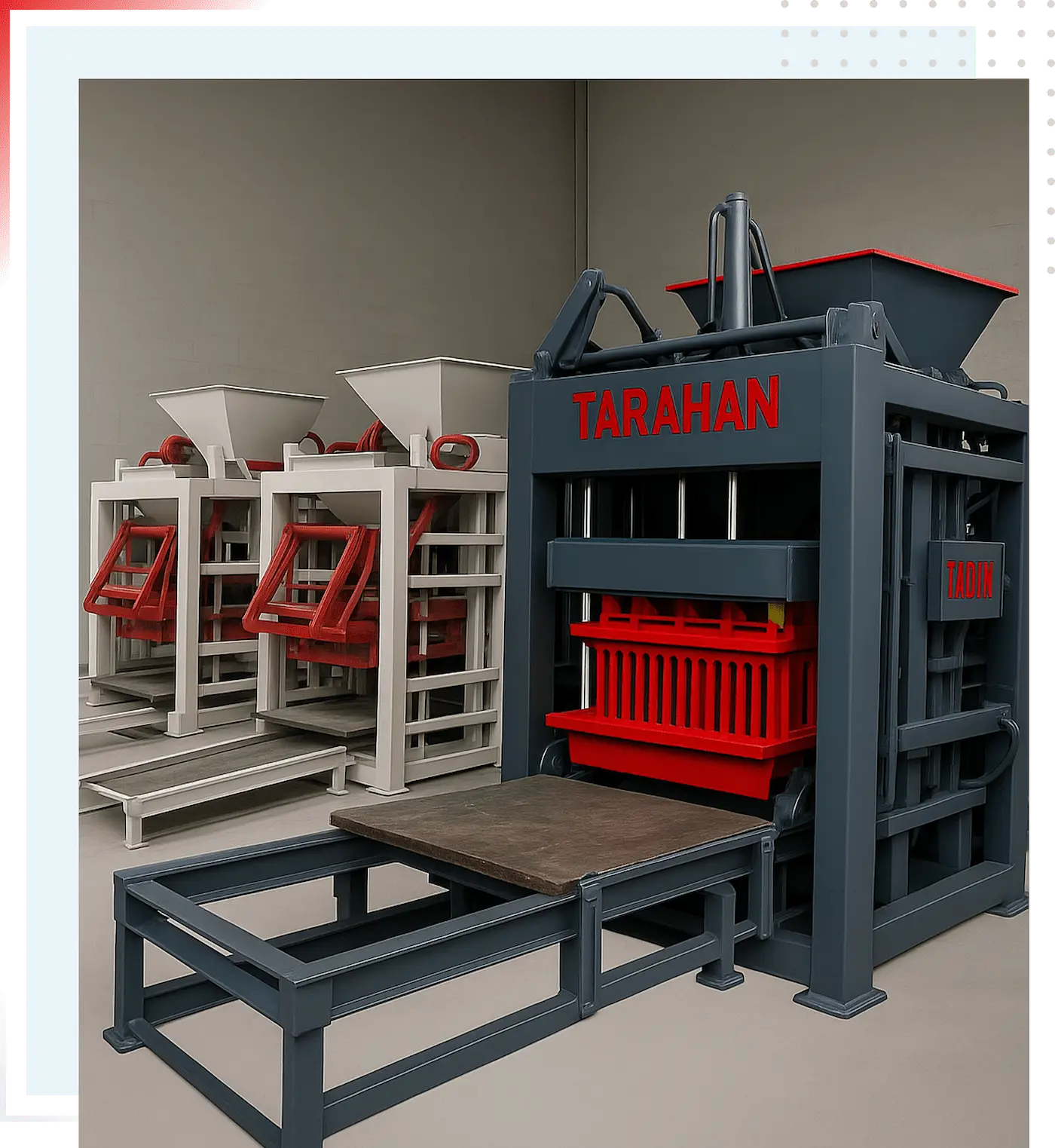

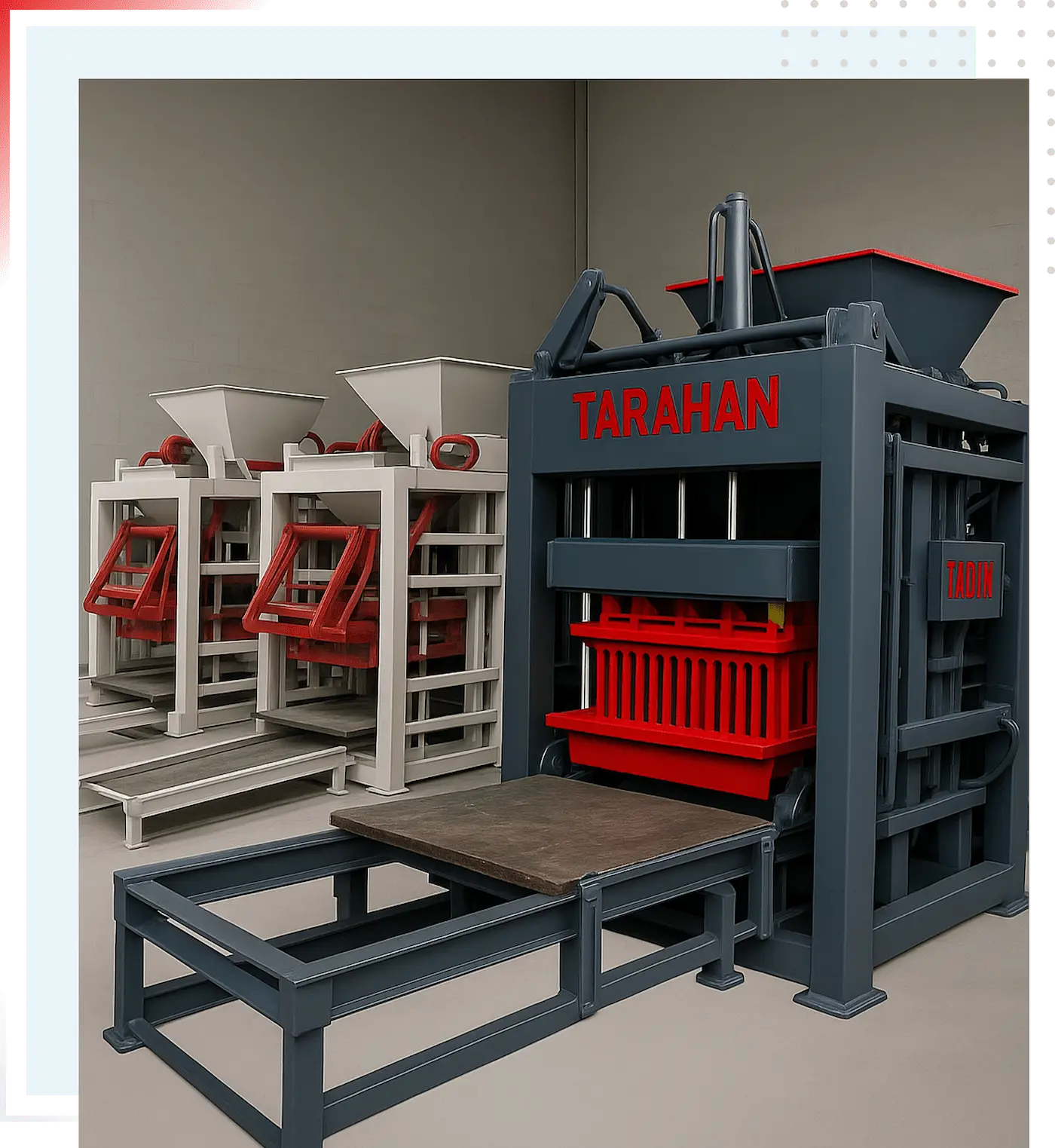

At Tarahan Machinery, we have designed and manufactured concrete paver machines to meet the needs of concrete product manufacturers and construction projects. These machines are available in single-bucket and double-bucket models and enable the production of various pavers in different molds and dimensions.

High manufacturing quality, suitable capacity, stable performance, and customization capability based on project needs are features that have made these machines a reliable choice for construction projects, municipalities, and building materials factories.

To review technical specifications, compare models, and receive purchase consultation, you can download the product catalog and then contact Tarahan Machinery sales experts for more information at 09145841914 Please contact us.

Buy Machine Paving Stone Production

Tarahan stationary concrete paver machine is designed for industrial production of various types of concrete pavers. These machines are installed as stationary units without mobility at the factory site and, utilizing advanced hydraulic systems and powerful vibrators, have the capability for continuous production of high-quality pavers with excellent dimensional accuracy.

The molds of these machines feature quick adjustment and replacement capabilities, enabling the production of various designs and thicknesses of pavers with wide and diverse dimensions during long work shifts.

Stationary Concrete Paver Machine Models

Why Tarahan Machinery?

High Production Capacity With significant increase in production efficiency

Cost Reduction Operational and manpower requirements

Production Capability Various concrete products

Support And 12-month warranty

10 Years of Service After-sales service and original spare parts supply

Fast Shipping Machine delivery to the entire country and neighboring countries

Concrete Paver Machine

The concrete paver production machine is one of the practical and high-efficiency equipment in the construction industry, used for producing various types of pavers, mosaics, and concrete paving stones. This machine, using interchangeable molds and press and vibration systems, enables the production of pieces with various designs, dimensions, and thicknesses.

Tarahan Machinery, a leader in industrial concrete machinery manufacturing, offers a complete range of paving stone and concrete paver production machines as a comprehensive response to construction and landscaping industry needs. These machines, from economical models for small workshops to advanced systems with high capacities, are all designed to optimize the production process, reduce costs, and ensure consistent final product quality.

Types of Paving Stone and Concrete Paver Production Machines Tarahan Machinery

Tarahan Machinery offers a comprehensive range of stationary paving stone and concrete paver production machines, each designed to meet specific needs of the concrete production industry. These machines are divided into two main categories based on feeding mechanism and color production capability:

Stationary Single-Bucket Machines: For Single-Color Concrete Paver Production

These machines are optimized using a single tank to produce single-color concrete pavers with high speed, consistent quality, and minimum operational costs. Single-bucket machines are ideal for mass production lines requiring standard and uniform products.

At Tarahan Machinery, single-bucket single-color paver production machines are as follows:

TM-108 Stationary Single-Bucket Concrete Paver Production Machine

TM-110 Stationary Single-Bucket Concrete Paver Production Machine

TM-112 Stationary Single-Bucket Concrete Paver Production Machine

TM-118 Stationary Single-Bucket Concrete Paver Production Machine

Stationary Double-Bucket Machines: For Two-Color and Decorative Concrete Paver Production

Double-bucket paving machines, using two separate tanks, enable the production of two-color and two-layer concrete pavers. These machines are designed to create decorative, interlocking, and high-value-added products that bring visual beauty and distinction to your projects.

At Tarahan Machinery, double-bucket color paver production machines are as follows:

TM-208 Stationary Double-Bucket Concrete Paver Production Machine

TM-210 Stationary Double-Bucket Concrete Paver Production Machine

TM-218 Stationary Double-Bucket Concrete Paver Production Machine

Comparison of Specifications for Various Tarahan Machinery Paver Production Machines

| Machine | Hopper Type | Pallet Size | Production Capacity (Per Shift) | 30×50 Curb Production Capacity per Press |

|---|---|---|---|---|

| TM-108 | Single Hopper | 99×92 | 450 | 0.8 |

| TM-208 | Double Hopper | 99×92 | 450 | 0.8 |

| TM-110 | Single Hopper | 115×110 | 650 | 1 |

| TM-210 | Double Hopper | 115×110 | 650 | 1 |

| TM-112 | Single Hopper | 145×110 | 750 | 1.4 |

| TM-118 | Single Hopper | 150×135 | 1200 | 1.8 |

| TM-218 | Double Hopper | 150×135 | 1200 | 1.8 |

Note: Listed production capacities are approximate and these numbers may vary depending on multiple factors

To contact the sales department and receive consultation about stationary curb machines, call 09145841914 Please contact us.

Important Factors in Selecting the Right Paving Stone Production Machine for Your Project

Paving stone production machine selection should be based on your project's and production line's actual needs. Below are the most important factors to consider:

Production Capacity and Pallet Dimensions

Machine production capacity (in terms of pallets per hour) and pallet dimensions play a direct role in your daily output and flexibility in producing various parts. In large urban or industrial projects, machines with high capacity and larger pallets usually perform better. Tarahan Machinery offers models with various capacities suitable for both mass production lines and small workshops.

Vibration and Hydraulic Systems

The precise operation of vibration and hydraulic systems in paver production machines has a direct impact on concrete compaction, final surface quality, and compressive strength. In machines using powerful industrial vibration and stable hydraulic systems, parts with high uniformity, low porosity, and greater durability are produced. This feature is well observed in models manufactured by Tarahan Machinery and visible in executed projects.

Production Line Automation Level

Sidewalk paving stone or concrete paver production machine is usually part of a complete production line and must be compatible with the overall automation level of the system. Depending on whether your production line is manual, semi-automatic, or fully automatic, the machine operation type must be selected. Tarahan Machinery, in addition to designing paving stone production machines, has also enabled full coordination with fully automatic lines to maintain high production efficiency and precision.

To receive specialized consultation on selecting the appropriate machine for your project type, required capacity, and desired automation level, you can contact Tarahan Machinery sales experts 04136304464 Please contact us.

Applications of Concrete Pavers Produced with Tarahan Machines

Concrete pavers produced with Tarahan machines are used in a wide range of projects due to their high quality, durability, and variety, bringing significant economic benefits:

Urban and Public Landscaping: Including sidewalks, parks, green spaces, and city squares that require durable and beautiful concrete pavers.

Residential and Commercial Projects: Used in villa yards, parking lots, residential complexes, and commercial spaces to create durable and attractive surfaces.

Industrial Projects and Warehouses: Concrete pavers are an ideal choice for flooring in factories, warehouses, and industrial spaces due to their high resistance to abrasion and heavy loads.

Decorative and Special Spaces: Using double-bucket paving machines, two-color and decorative concrete pavers can be produced for use in designing special and luxury spaces.

Tarahan Machinery Concrete Paver Production Machine Price

The price of paving stone machine varies depending on the selected model, production capacity, pallet dimensions, and production line auxiliary equipment; at Tarahan Machinery, the approximate price range for all stationary concrete paver production machines (considering the selected model, mold, and equipment) is between 1 to 5 billion Tomans.

Factors Affecting Paver Machine Price:

Machine Model: Each model (such as TM-104, TM-108, TM-208, TM-210, TM-218) has different technical specifications and capacities that affect the final price.

Mold Type and Quantity: Selection of various molds for producing different shapes of concrete pavers is included in the final cost.

Production Line Auxiliary Equipment: The machine price may include complementary equipment such as concrete mixer, batching plant, and conveyor belt.

To receive an accurate and up-to-date price inquiry for paving stone (concrete paver) production machine and free technical consultation before purchase, contact our sales experts now: 04136304464

Process of Purchasing Paving Stone Production Machine from Tarahan Machinery

Tarahan Machinery has simplified and clarified the process of purchasing paving stone (concrete paver) production machines for its customers. We are with you at all stages, from selection to commissioning, to ensure a reliable and efficient purchasing experience:

Initial Consultation and Needs Assessment: Initially, our specialized experts recommend the best paver machine model and production line equipment by carefully examining your project needs, production scale, and budget.

Proforma Invoice Issuance and Contract Signing: After confirming the model and equipment, an official proforma invoice is issued and a purchase contract is concluded with complete and transparent details.

Production and Preparation: Your machine is manufactured according to contract specifications using the best materials and highest engineering standards.

Shipping and Delivery: Your machine will be shipped with safe packaging via ground transportation throughout Iran. The delivery time is between 60 to 70 working days after contract signing.

On-Site Installation and Setup: Tarahan Machinery's specialized technical team will be present at your project site for complete installation and commissioning of the concrete paver production machine.

Complete Operator Training: During installation, comprehensive and practical training is provided to your personnel and operators so they can operate the production line optimally and safely.

Payment Terms: Tarahan Machinery provides cash and installment sales up to 6 months (subject to relative stability in the currency market and condition approval) to facilitate your investment.

Warranty and After-Sales Services for Tarahan Concrete Paver Production Machines

Tarahan Machinery provides a comprehensive and organized set of technical and support services to support paver machine users:

12 Months Full Manufacturing Warranty: All Tarahan paver production machines are covered by a one-year warranty. This warranty covers any defects related to the manufacturing process during the first year of operation.

10 Years Active After-Sales Service: Supply of original spare parts, technical support in various periods, and rapid response to repair and maintenance needs are on the agenda up to 10 years after purchasing the machine. This support is provided with the goal of reducing production downtime and increasing equipment lifespan.

Remote Technical Consultation and Guidance: In case of technical issues or need for operational guidance, technical experts are available via phone call or online consultation to provide accurate and immediate solutions.

Dispatch Expert to Project Site: In cases where the problem requires on-site inspection, technical personnel can be dispatched to the machine installation site for inspection, service, or specialized troubleshooting.

Operator Training at Installation Site: Simultaneously with the installation and commissioning of the paving machine, complete practical training is provided to operators to ensure the operation process is performed with precision, safety, and maximum efficiency.