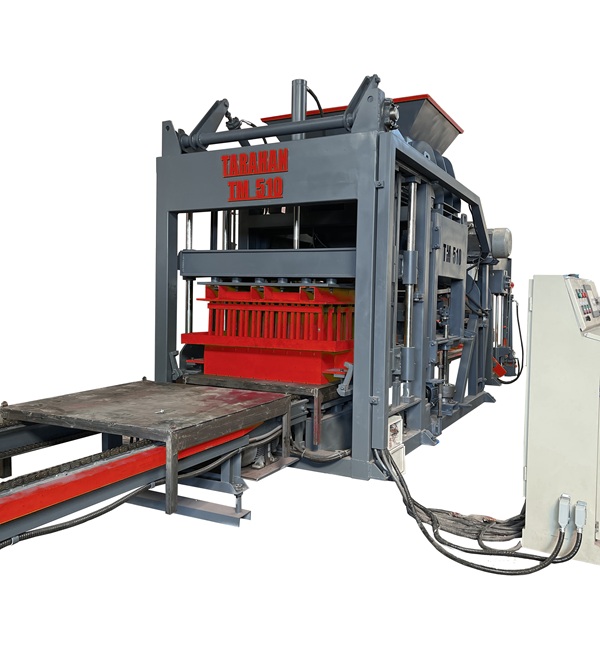

Tarahan Brick Press Machine

The Tarahan brick press machine is designed for producing various types of bricks, including Lefon bricks, firebricks, perlite bricks, clay bricks, puzzle bricks, and facing bricks. These presses are available in capacities ranging from 60 to 600 tons.

Tarahan Brick Press Models

| Model | Press Power (Ton) | Table Size (cm) | Machine Dimensions (cm) | Motor Power (kW) | Weight (Tons) |

|---|---|---|---|---|---|

| T.BP 60 | 60 | 60 × 60 | 268 × 80 × 155 | 7.5 | 2 |

| T.BP 100 | 100 | 70 × 70 | – | 11 | 3 |

| T.BP 150 | 160 | 80 × 80 | – | 15 | 4 |

| T.BP 200 | 200 | 90 × 90 | 448 × 160 × 260 | 22 | 6 |

| T.BP 300 | 315 | 100 × 100 | 532 × 210 × 315 | 37 | 7 |

| T.BP 400 | 400 | 120 × 120 | 587 × 220 × 330 | 50 | 8 |

| T.BP 600 | 630 | 160 × 160 | 843 × 264 × 400 | 84 | 12 |

T.BP 60 Puzzle Brick Press Machine

This compact brick press is specifically designed for producing puzzle bricks. The machine produces two puzzle bricks per cycle with dimensions of 25 × 12.5 × 6.5 cm, and it can produce up to 2500 puzzle bricks per day.

Frequently Asked Questions

How can I choose the right brick press machine for my business needs?

Consider factors such as desired production output, preferred brick types (e.g., clay bricks, firebricks, machine-made bricks, puzzle bricks, ceramic bricks, and glazed bricks), raw materials, and budget. The machine should align with your production scale and operational efficiency.

What are the key features of a high-quality brick press machine?

Essential features include user-friendliness, durability, high efficiency, energy savings, and the ability to produce bricks that meet industrial standards.

What is the difference between fully automatic and semi-automatic brick machines?

Fully automatic machines are engineered to operate with minimal manual labor, efficiently handling tasks such as material feeding and brick pressing, often using Programmable Logic Controllers (PLC) for autonomous operation.

Can I find a brick press machine that accommodates different raw materials?

Yes, versatile machines are available that can handle materials such as fly ash, crushed stone, and lime. Always check the machine specifications or consult the supplier for material compatibility.

What are the benefits of hydraulic press systems in brick production?

Hydraulic press systems ensure consistent pressure, which improves brick quality, resulting in stronger, smoother bricks. They also apply higher compression force, which is essential for specialty bricks.

How can I ensure the brick press machine meets safety and quality standards?

Tarahan Machinery guarantees the use of standard-quality components from renowned global brands. All parts are pre-listed in the proforma invoice and delivered exactly as specified to the customer.

What factors should I consider when selecting the machine capacity?

Think about your business’s production volume needs, available space, and the specific types of bricks you plan to manufacture. Choose a machine with a capacity that fits your production requirements without exceeding your workspace limitations.

Can the brick press machine be customized to meet specific needs?

Yes, many suppliers offer customization options, including size modifications and feature enhancements. Communicating your exact requirements with the supplier ensures the machine meets your business needs.

What is the warranty on Tarahan brick machines, and do they come with after-sales service?

Yes, all Tarahan machines come with a 1-year warranty and 10 years of after-sales service.

How can I maintain my brick press machine for long-term durability?

Regular maintenance, including cleaning, hydraulic system inspections, and software updates, extends the lifespan of your machine. Following the manufacturer’s guidelines is crucial to maintaining the machine’s optimal performance.

Is the brick press machine tested before shipment?

Yes, all machines undergo testing after production and before shipment. Regardless of whether the customer is present or not, hydraulic pressure, press movement, mold operation, and other key aspects are tested. These results are recorded in an F.A.T (Factory Acceptance Test) document and filed under the customer’s records.

What does after-sales service for brick press machines include?

After-sales services vary by supplier but typically include online support, video technical assistance, expert dispatch for maintenance, and periodic servicing and repairs. Always review the scope of after-sales services before finalizing your purchase.