Line Concrete Parts Production

Tarahan Machinery, a pioneer in designing and producing advanced concrete parts production machinery, designs and offers concrete product production lines including manual, semi-automatic, automatic, and fully automatic lines. These lines, utilizing modern technologies and designs suited to various needs, enable the production of blocks, curbs, pavers, and flower boxes with high quality and optimal productivity for small to large workshops and factories.

At Tarahan Machinery, relying on expert consultation, concrete parts production machines are customizable so that the best production line suited to your needs can be selected.

Why Tarahan Machinery?

High Production Capacity With significant increase in production efficiency

Cost Reduction Operational and manpower requirements

Production Capability Various concrete products

Support And 12-month warranty

10 Years of Service After-sales service and original spare parts supply

Fast Shipping Machine delivery to the entire country and neighboring countries

Tarahan Machinery

Aware of the diversity of needs and different scales of activity in the concrete parts production industry, Tarahan Machinery offers 4 types of production lines. This classification is defined based on automation level and product collection methods so that every producer can find an option suited to their capital, available space, manpower, and desired production volume.

In the following, the features, main machinery, and product collection methods for each of these production lines are described in detail.

To contact the sales department and receive consultation about concrete parts production lines, call 09145841914 Please contact us.

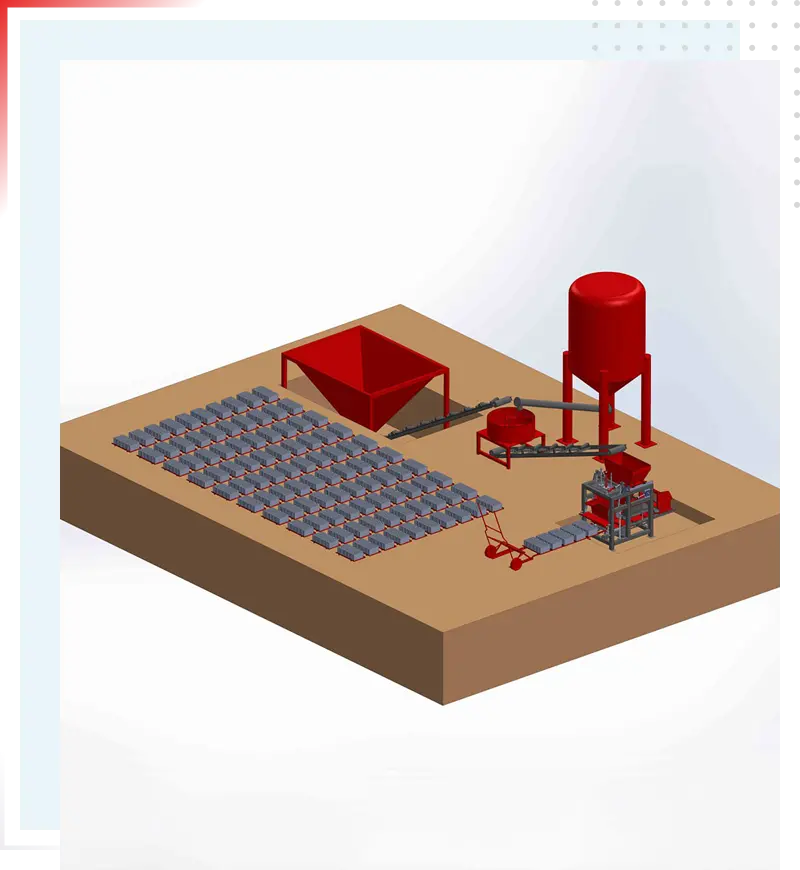

Production Line Manual

The manual concrete parts production line is an economical option with low initial investment, designed for small workshops, new producers, or projects with limited production volume. This type of production line, which is the simplest and cheapest production line from Tarahan Machinery, focuses on operational simplicity and reducing initial costs.

Product Collection Method Concrete in Manual Production Line

Output products from this production line can be moved using two tools:

Wheelbarrow

In the manual production line with wheelbarrow, output products on pallets are manually transported from the machine with a special wheelbarrow, and then the pallets are arranged side by side on the ground until dry.

Elevator/Rack

If the elevator and rack system is used for transporting and collecting concrete parts products, the products are arranged side by side on the ground after production and transferred by one person to the desired location. This type of manual production line system with elevator and rack takes up less space compared to the wheelbarrow.

Main Machinery Manual Production Line

Batching Plant

Block/Curb/Paver Production Machine

Simple Metal Pallet

800-Liter Mixer

Rack System

Wheelbarrow System

Specifications Table Manual Production Line

| Feature | TM-400 Model (Wheelbarrow) | TM-400 Model (Rack, Elevator) | TM-502 Model (Wheelbarrow) | TM-502 Model (Rack, Elevator) |

|---|---|---|---|---|

| Transfer System | Wheelbarrow | Rack, Elevator | Wheelbarrow | Rack, Elevator |

| Pallet Size (cm) | 87×46 | 87×46 | 92×98 | 92×98 |

| Human Resources | 4 | 4 | 4 | 4 |

| Land Area (m²) | 1000 | 600 | 1500 | 1000 |

| Power (kW) | 47 | 50 | 52 | 55 |

| Block Production Capacity* | 4000 pieces | 4000 pieces | 6000 pieces | 6000 pieces |

| Block Size 20 Capacity** | 4 | 4 | 8 | 8 |

| Block Size 15 Capacity** | 5 | 5 | 10 | 10 |

| Block Size 10 Capacity** | 7 | 7 | 16 | 16 |

| Curb Production Capacity* | - | - | 800 pieces | 800 pieces |

| Curb Size 30×50 Capacity** | - | - | 3 | 3 |

| Paving Stone Capacity* | 200 square meters | 200 square meters | 450 square meters | 450 square meters |

| Paving Stone Capacity** | 0.3 square meters | 0.3 square meters | 0.8 square meters | 0.8 square meters |

Production capacity is calculated per 8 hours.

Production capacity is calculated per cycle.

Note: Manpower and land area are calculated as minimum, and production capacity depends on workforce skill, 1000 pallets, and minimum equipment requirements.

Very low startup cost

Requires less space compared to other production lines

Simpler operation and maintenance of machinery

Low production capacity

High dependence on human labor

Product quality and uniformity affected by operator skill

Tarahan Machinery experts are ready to provide consultation.

Contact Tarahan Machinery Experts

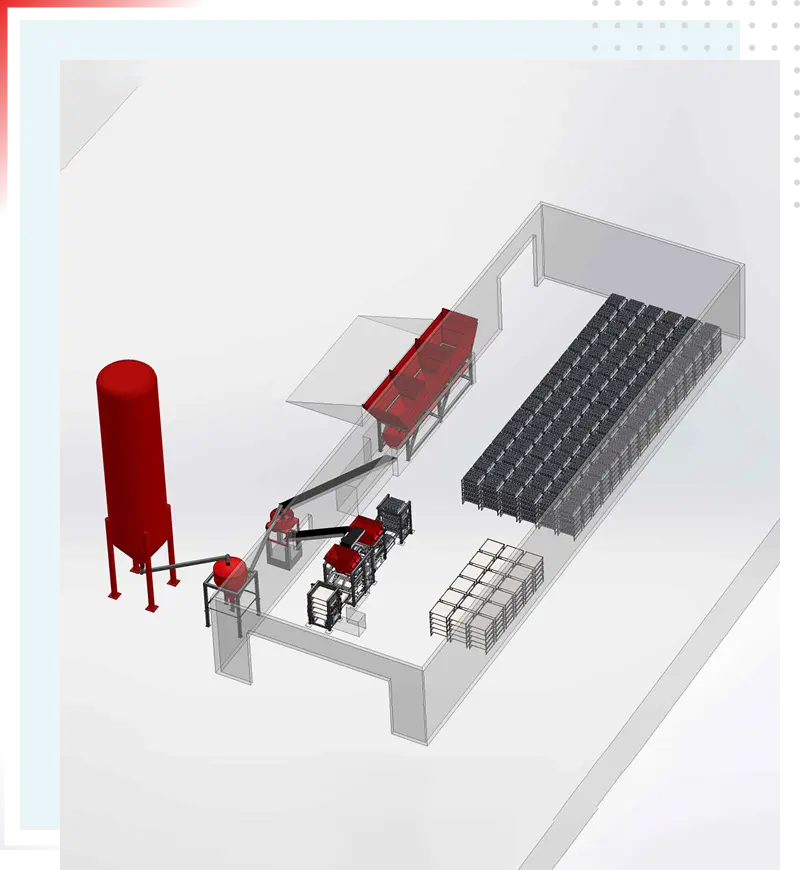

Production Line Semi-Automatic

The semi-automatic concrete parts production line is a step beyond the manual system and is designed to balance initial investment, productivity, and product quality. This type of production line is equipped with a forklift, and lifting and lowering robots are positioned at the front and back of the machine. Empty pallets are fed by the lowering robot from the back of the machine, and after products are produced on the pallets, they are stacked by the lifting robot at the front of the machine and then loaded by the forklift from the robot and transferred to the drying area.

Product Collection Method Concrete in Semi-Automatic Production Line

Output products from the semi-automatic production line can be moved using a forklift:

Main Machinery Semi-Automatic Production Line

Batching Plant

Block/Curb/Paver Production Machine

Lifting and Lowering Robot

Mixer

Legged Metal Pallet

Specifications Table Semi-Automatic Production Line

| Feature | Model TM-502 | Model TM-508 | TM-510 Model | TM-510 Model | Model TM-512 | Model TM-518 | Model TM-536 |

|---|---|---|---|---|---|---|---|

| Machine Type | Single Hopper | Double Hopper | Single Hopper | Double Hopper | Single Hopper | Single Hopper | Double Hopper |

| Batching Plant | 40 | 60 | 60 | 60 | 80 | 80 | 100 |

| Mixer (Liter) | 800 | 800 | 1000 | 1000 | 1200 | 2000 | 2000 |

| Power (kW) | 62 | 64 | 66 | 82 | 92 | 98 | 100 |

| Block Production Capacity* | 6000 | 6000 | 8000 | 8000 | 10000 | 12000 | 12000 |

| Block Size 20 Capacity** | 8 | 8 | 10 | 10 | 12 | 18 | 18 |

| Block Size 15 Capacity** | 10 | 10 | 12 | 12 | 16 | 27 | 27 |

| Block Size 10 Capacity** | 16 | 16 | 18 | 18 | 24 | 39 | 39 |

| Curb Production Capacity* | 800 | 800 | 3500 | 3500 | 5000 | 5000 | 5000 |

| Curb Size 30×50 Capacity** | 3 | 3 | 6 | 6 | 8 | 8 | 8 |

| Paving Stone Capacity* | 450 square meters | 450 square meters | 650 square meters | 650 square meters | 750 square meters | 1200 square meters | 1200 square meters |

| Paving Stone Capacity** | 0.8 square meters | 0.8 square meters | 1 square meter | 1 square meter | 1.4 square meters | 1.8 square meters | 1.8 square meters |

Production capacity is calculated per 8 hours.

Production capacity is calculated per cycle.

Note: Manpower of 6 people and land area of 2000 square meters are calculated as minimum. Production capacity depends on workforce skill, 1000 pallets, and minimum requirements.

Significant increase in production capacity compared to manual line

Improved quality and product uniformity using batching and more advanced equipment

Relative reduction in required manpower

Requires more initial investment compared to manual line

Requires more space for equipment setup

"If your goal is mass production and high efficiency in large projects, concrete parts production line machines are a more suitable option; but for smaller projects or the need for more mobility and flexibility, concrete parts production line machines will be a better choice."

Tarahan Machinery experts are ready to provide consultation.

Contact Tarahan Machinery Experts

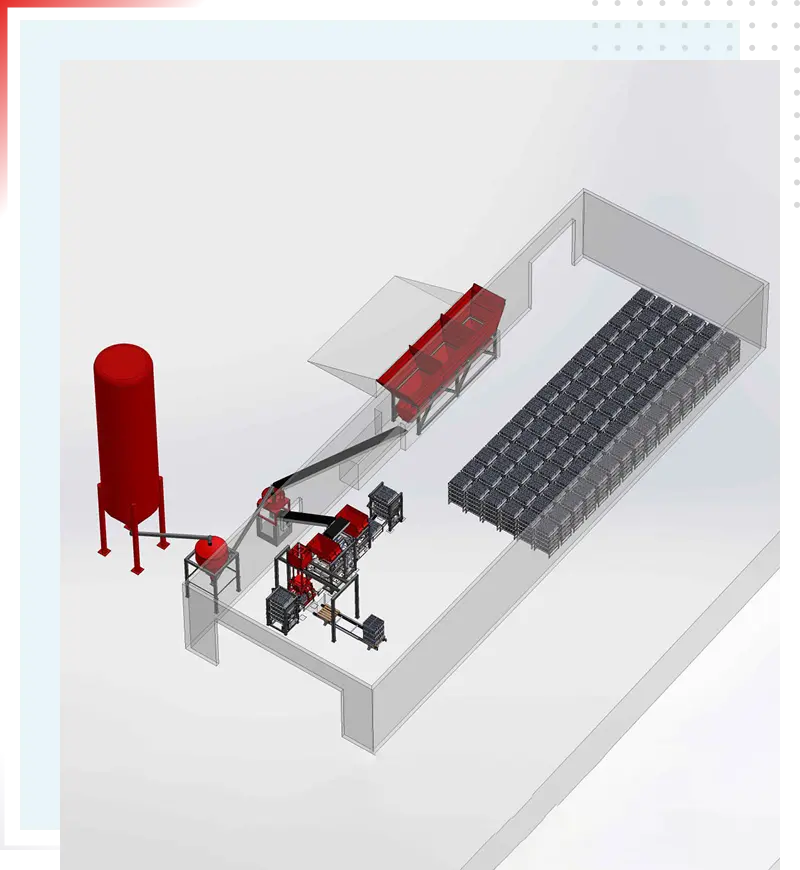

Production Line Automatic

Tarahan Machinery's automatic concrete parts production line is a mechanized and advanced system for producing various concrete parts including blocks, curbs, and paving stones, designed based on PLC technology and industrial robotics. In this line, all processes from raw material weighing to final product arrangement are performed fully automatically without the need for human labor.

Product Collection Method Concrete in Automatic Production Line

In the automatic concrete parts production line, after the products are formed on pallets and processed, it's time for collection and arrangement for packaging or transfer. This stage in the Tarahan Machinery system is fully mechanized, and robots handle this task instead of human labor.

In this part of the production line, two types of robots can be used:

Cuber Robot (Collecting Robot)

Paddle Robot (Sliding)

Both robots are responsible for picking up dried products from the production pallet and arranging them in a specific order on sales or transport pallets. Their difference is mainly in the type of operation and required investment level. The collecting robot works with high precision and adjustability and is suitable for high-volume lines. In contrast, the paddle robot is a more economical option that moves parts with a sliding motion and is an ideal choice for projects with lower capacity or limited budget.

Using this system makes the product collection process faster, more accurate, and without the need for manual intervention; as a result, both time is saved and damage to products is minimized.

Main Machinery Automatic Production Line

Concrete Parts Production Machine (Block, Curb, Paver)

Batching Plant

Mixer

Lifting/Lowering Robot

Collecting Robot

Paddle System

Legged Pallet

Specifications Table Semi-Automatic Production Line

| Feature | Model TM-502 | Model TM-508 | TM-510 Model | TM-510 Model | Model TM-512 | Model TM-518 | Model TM-536 |

|---|---|---|---|---|---|---|---|

| Batching Plant | 40 | 60 | 60 | 60 | 80 | 80 | 100 |

| Mixer (Liter) | 800 | 800 | 1000 | 1000 | 1200 | 2000 | 2000 |

| Power (kW) / Palletizing Robot | 54 | 56 | 58 | 74 | 84 | 90 | 92 |

| Power (kW) / Collecting Robot | 62 | 64 | 66 | 82 | 92 | 98 | 100 |

| Block Production Capacity* | 6000 | 6000 | 8000 | 8000 | 10000 | 12000 | 12000 |

| Block Size 20 Capacity** | 8 | 8 | 10 | 10 | 12 | 18 | 18 |

| Block Size 15 Capacity** | 10 | 10 | 12 | 12 | 16 | 27 | 27 |

| Block Size 10 Capacity** | 16 | 16 | 18 | 18 | 24 | 39 | 39 |

| Curb Production Capacity* | 800 | 800 | 3500 | 3500 | 5000 | 5000 | 5000 |

| Curb Size 30×50 Capacity** | 3 | 3 | 6 | 6 | 8 | 8 | 8 |

| Paving Stone Capacity* | 450 square meters | 450 square meters | 650 square meters | 650 square meters | 750 square meters | 1200 square meters | 1200 square meters |

| Paving Stone Capacity** | 0.8 square meters | 0.8 square meters | 1 square meter | 1 square meter | 1.4 square meters | 1.8 square meters | 1.8 square meters |

Production capacity is calculated per 8 hours.

Production capacity is calculated per cycle.

Note: Manpower of 5 people and land area of 2500 square meters are calculated as minimum, and production capacity depends on workforce skill, 1000 pallets, and minimum requirements.

Significant reduction in manpower requirements due to fully automatic operation and PLC control

Increased capacity and production speed with full coordination and production stage continuity

Guarantee of high quality and product uniformity with precise control at all stages

High productivity with waste reduction, time savings, and energy consumption optimization

High initial investment for purchasing and setting up equipment

Need for larger space for installing advanced machinery

Dependence on specialized personnel for setup, maintenance, and troubleshooting

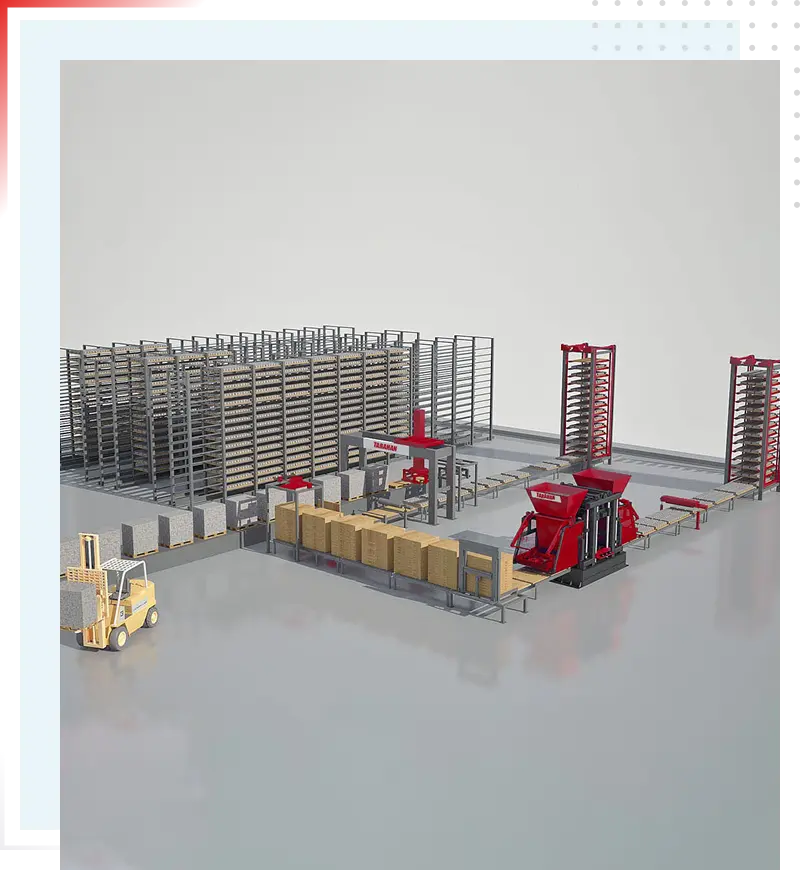

Production Line Fully Automatic

The fully automatic concrete parts production line is the most advanced production line offered by Tarahan Machinery, designed to achieve maximum efficiency, minimum human intervention, and complete process integration, from raw material preparation to final product packaging. This level of automation typically includes more advanced control systems, multiple sensors, and more extensive robotics compared to automatic lines.

In Tarahan Machinery's fully automatic production line, all stages from material weighing (gravel, sand, pumice) with digital feeder to mixing in DM.H horizontal mixer and TM series mold pressing are under integrated PLC control. The drying unit is installed on precise rails and powered with industrial wiring so that parts dry with minimal heat loss in the shortest time after forming.

Instead of traditional lifting and lowering robots, the system uses a finger car for pallet transfer and a combination of elevator and lowerator for multi-level pallet stacking, a design that significantly increases production capacity while reducing manpower.

Product Collection Method Concrete in Fully Automatic Production Line

In this system, the product collection process from pallets is fully mechanized and performed without manual intervention. After the drying process ends, the finger car removes the pallets containing concrete parts from the rail path and delivers them to the elevator system. The elevator raises the pallets to a specific height, and then the lowerator places them in an orderly manner in multiple stacks on the unloading or packaging station. In addition to high transfer speed, this method ensures that parts are prepared for storage or shipping without damage and completely organized. The result of this process is increased productivity, reduced errors, and faster preparation of final products.

Main Machinery Fully Automatic Production Line

Batching Plant

Concrete Parts Production Machine (Block, Curb, and Paver)

Mixer

Elevator / Lowerator / Finger Car

Collecting Robot

Pallet

Specifications Table Semi-Automatic Production Line

| Feature | Model TM-502 | Model TM-508 | TM-510 Single Hopper Model | TM-510 Double Hopper Model | Model TM-512 | Model TM-518 | Model TM-536 |

|---|---|---|---|---|---|---|---|

| Pallet Size | 92×98 | 92×98 | 110×115 | 110×115 | 142×92 | 150×135 | 150×135 |

| Batching Plant | 40 | 60 | 60 | 60 | 80 | 80 | 100 |

| Mixer (Liter) | 800 | 800 | 1000 | 1000 | 1200 | 2000 | 2000 |

| Power (kW) | 153 | 156 | 186 | 189 | 206 | 221 | 225 |

| Block Production Capacity* | 6000 | 6000 | 8000 | 8000 | 10000 | 12000 | 12000 |

| Block Size 20 Capacity** | 8 | 8 | 10 | 10 | 12 | 18 | 18 |

| Block Size 15 Capacity** | 10 | 10 | 12 | 12 | 16 | 27 | 27 |

| Block Size 10 Capacity** | 16 | 16 | 18 | 18 | 24 | 39 | 39 |

| Curb Production Capacity* | 800 | 800 | 3500 | 3500 | 5000 | 5000 | 5000 |

| Curb Size 30×50 Capacity** | 3 | 3 | 6 | 6 | 8 | 8 | 8 |

| Paving Stone Capacity* | 450 square meters | 450 square meters | 650 square meters | 650 square meters | 750 square meters | 1200 square meters | 1200 square meters |

| Paving Stone Capacity** | 0.8 square meters | 0.8 square meters | 1 square meter | 1 square meter | 1.4 square meters | 1.8 square meters | 1.8 square meters |

Production capacity is calculated per 8 hours.

Production capacity is calculated per cycle.

Maximum productivity and efficiency with full automation and process continuity

Minimal need for human resources and significant reduction in human errors and personnel costs

Comprehensive quality control at all production stages using sensors and feedback systems

Capability for continuous 24-hour production with precise maintenance planning

Ability to achieve the highest quality and quantity standards in production

Need for very high initial investment

Complete dependence on advanced infrastructure and modern technology

Complexity in setup, maintenance, and repairs requiring specialized personnel

High system sensitivity to software or electrical disturbances

Tarahan Machinery experts are ready to provide consultation.

Contact Tarahan Machinery Experts

Smart Selection Guide Tarahan Machinery Production Lines Comparison Table

| Feature | Fully Automatic Production Line | Automatic Production Line | Semi-Automatic Production Line | Manual Production Line |

|---|---|---|---|---|

| Automation Level | Full automation with PLC and advanced robotic systems | High automation with robot and PLC | Limited automation (Lifting/Lowering Robot) | No automation |

| Product Collection | Finger Car + Elevator + Lowerator | Cuber Robot or Paddle Robot | Forklift + Lifting/Lowering Robot | Wheelbarrow / Elevator and Rack |

| Human Resources (Minimum) | 3 to 4 people | 5 people | 6 people | 4 people |

| Space Required (m²) | Minimum 3000 | Minimum 2500 | Minimum 2000 | 600 to 1500 |

| Power Consumption (kW) | 153 to 225 (depending on production machine) | 54 to 92 (depending on production machine) | 62 to 100 (depending on production machine) | 47 to 55 (depending on production machine) |

| Block Production Capacity per Shift | 6000 to 12000 pieces (depending on production machine) | 6000 to 12000 pieces (depending on production machine) | 6000 to 12000 pieces (depending on production machine) | 4000 to 6000 pieces (depending on production machine) |

| Curb Production Capacity per Shift | 800 to 5000 pieces | 800 to 5000 pieces | 800 to 5000 pieces | 800 pieces |

| Paving Stone Capacity per Shift | 450 to 1200 square meters (depending on production machine) | 450 to 1200 square meters (depending on production machine) | 450 to 1200 square meters (depending on production machine) | 200 to 450 square meters (depending on production machine) |

| Pallet Type Used | Heavy industrial pallet with large size | Durable legged pallet for robot | Legged metal | Simple or legged metal |

| Advantages | Maximum productivity, complete quality control | Reduced manpower, uniform quality | Cost and production balance, better quality | Low capital, quick setup |

| Limitations | Very high investment, requires strong infrastructure | High cost, requires technical expertise | Requires more space and capital | Low capacity, operator dependency |

| Suitable For | Export producers or national projects | Large factories with high output | Medium factories | Small workshops or custom production |

Note: Some explanations are provided based on general industry information; for accurate information about Tarahan Machinery production lines, consulting with company experts is essential.

Concrete Parts Production Line Machinery Tarahan Machinery

The success and efficiency of every concrete parts production line depends on the quality and coordination of its component machines. Relying on its experience and technical knowledge, Tarahan Machinery produces and supplies a collection of main and auxiliary machines that form the backbone of this company's manual, semi-automatic, automatic, and fully automatic production lines.

Getting familiar with these machines helps you better understand production lines and the function of each one. In this section, we review the main equipment of production lines together:

Batching Plant Systems

The batching plant system is the starting point of the concrete production process and one of the important parts in ensuring the quality of concrete parts. The function of this system is to accurately measure and initially mix the main concrete materials including cement, aggregate, water, and additives based on the specified mix design. Understanding the key role of this stage in the final product quality, Tarahan Machinery offers a diverse range of batching plant systems that are at a high level in terms of performance accuracy and reliability. At Tarahan Machinery, we produce and supply various types of batching plants including stationary, portable, and mobile models, and you can start your intended industrial project based on project needs, choosing from any of these three types of batching plants and the required amount of wet and dry concrete.

Various Models: Manual machines are cheaper, and fully automatic stationary production lines are the most expensive options.

Diverse Capacity: Stationary, portable, and mobile – suitable for every project scale

Precise Control: From 30 to 160 cubic meters per hour

Robust Structure: Fully automatic PLC systems with high weighing accuracy (±0.5% error)

Full Support: 12-month warranty, 10 years of after-sales service and parts supply, continuous technical services

Tarahan Machinery emphasizes the importance of proper foundation for installing various batching plant sections and observing safety points in the design and operation of these systems. The precision in weighing raw materials, guaranteed by Tarahan's advanced batching systems, directly affects the strength, durability, and uniformity of produced concrete parts and also prevents material waste.

Tarahan Concrete Mixers

Tarahan Machinery mixers are produced and supplied in wet and dry types, with WM series models for wet mixers and DM series for dry mixers. Wet mixers, which are used in batching plants for ready-mix concrete preparation, are designed and produced in the following 4 models:

Drum Mixer

Single Shaft Mixer

Twin Shaft Mixer

Planetary Mixer

DM series dry mixers, also known as dry mortar mixers, are used for mixing semi-dry materials, and their mortar is used to produce concrete parts such as blocks, curbs, and pavers. Mixers in this series are produced and available in two models: horizontal and vertical.

Double-wall wear-resistant body, durable paddles with replacement capability

Powerful electric gearboxes for uniform performance under high working pressure

Compatible with various materials, from fluid grouts to semi-dry and aggregate mortars

Low maintenance cost with optimized design for easy repairs and replaceable consumable parts

High efficiency alongside uniform and stable mixing quality

Suitable for block, curb, paver, artificial stone, precast parts, and special structure production lines

Stationary Concrete Parts Production Machines (Block Making, Curb Making, Paver Making)

Stationary concrete parts production machines are the central equipment in every production line, responsible for shaping and compacting the concrete mixture into the final product (blocks, curbs, pavers, and flower boxes). Tarahan Machinery offers a series of stationary machines called the TM series, which meet the various needs of manufacturers with different capacities, features, and automation levels.

One of the strengths of Tarahan Machinery TM series machines is the adaptability and versatility of many models. For example, a concrete parts production machine like the TM-510 can also be used for paver and curb production by changing the mold. This flexibility is very valuable for manufacturers seeking product diversity.

All these stationary machines utilize powerful vibration systems for optimal concrete compaction and hydraulic systems for applying pressure and precise mechanical movements. Therefore, choosing the right model depends on the dominant product type, required production volume, and investment amount.

Keep in mind that choosing the right mixer ensures achieving quality concrete and, consequently, producing standard and durable concrete parts.

For more information and consultation about Tarahan Machinery mixers, contact our experts at 09145841914.

Price Concrete Parts Production Line

The price of concrete parts production equipment varies depending on the machine type, capacity, customized molds, parts used, etc. The entire production line, from manual to fully automatic, has a variable price between 2 to 15 billion Tomans. Due to the need for less manpower and advanced technologies, the fully automatic production line has the highest setup cost, and therefore this type of production line is recommended for very large industrial projects with export potential.

Determining Factors for Concrete Parts Production Line Pricing

Pricing a concrete parts production line depends on multiple factors. At Tarahan Machinery, TM series stationary lines and their complementary equipment are offered in a range between $25,000 to $250,000. This price difference reflects diversity in capacity, equipment type, automation level, and customization options.

Automation Level: Manual, semi-automatic, automatic, or fully automatic – the higher the automation, the higher the initial cost, but higher productivity and long-term savings.

Production Capacity: Lines with higher capacity = heavier equipment and higher price.

Main Equipment Type: Selection of mixer type, batching plant, concrete parts production machine, robots, and packaging.

Customization: Custom design or specific settings according to customer needs.

Auxiliary Equipment: Molds, conveyors, silos, finger cars, pallets, etc.

Installation and Setup Services: Including training, initial setup, and operator support.

Parts Quality: Use of European parts with high durability and reliable performance.

For free expert consultation and accurate price inquiry, contact us through one of the following methods. 09145841914

Steps for Purchasing Concrete Parts Production Line Equipment from Tarahan Machinery

Consultation and needs assessment by reviewing customer resources and recommending suitable equipment

Finalizing the order and sending proforma invoice to the customer

In-person meeting for contract signing or final invoice issuance

Machine delivery to the project site on schedule

Tarahan Machinery Services for Purchasing Concrete Production Line Equipment

Tarahan Machinery is not just an equipment supplier; it is your technical and business partner in establishing and developing concrete parts production lines. Our services start from the consultation and design stage and continue through long-term technical support, training, parts supply, and system upgrades.

Pre-Purchase Consultation: Optimal machine selection based on capacity, budget, and project space

Custom Design: Complete adaptation of machinery to your specific production conditions

On-Site Installation and Setup: Including operator training and operational testing

Warranty and After-Sales Service: Up to 10 years of technical support, on-site and remote

Fast Spare Parts Supply: Use of original parts and delivery in the shortest time

Reliable Shipping: Safe packaging and transportation with on-time delivery to project site

Future Upgrade Capability: Possibility of control system updates or equipment upgrades as needed

With these services, Tarahan stands by you to ensure stable, uninterrupted, and profitable production.